Punching/Drilling/Perforating

- 1. PMC or Busch type punching machines are optimal for YUPO, but other types can also be used. Victors, Thomson, Orton, Bobst, and Heidelberg, etc. can be used.

- 2. One-sided or two-sided blades can be used, but blades must be sharp and free of nicks. If the blades are not sharp, the edge will be prone to napping, and removing the nap may cause delamination.

- 3. Right angles and sharp corners may cause tearing, so be sure to design the material with rounded corners before punching it.

- 4. When using machines other than PMC- or Busch-type machines, set the blade that comes into contact with the back plate so that it touches it lightly to prevent damage to the blade. Also, adequately remove any unevenness. If the blades get crushed or nicked, this may cause a nap to appear on YUPO or delamination.

- 5. Set the interface of the punching die to a position that follows the grain of YUPO, and narrow it as much as possible to improve the workability of removing napping.

- 6. When removing napping, take care to prevent tearing and napping of the YUPO.

- 7. For die cutting using a rotary die, consult with the die manufacturer in advance to select a die (blade) that meets the required performance. Normally, ultra-high speed steel is used, and the blade angle is set to 22 to 25°.

- 1. Use a drill with a diameter of 6 mm or more, and ensure that it is sharp and free of nicks. If the drill diameter is too small, the sheets can bend. If the drill is not sharp, after marks may fuse to damage the drill blade.

- 2. Expel the air from between the sheets prior to drilling.

- 3. The height of the paper to be drilled at one time should not exceed 20 mm.

- 4. If the openings become fused, allow the drill to cool or replace it with a new one.

- 1. Use machine blades that are sharp and free of nicks.

- 2. Create perforations that are accurately in a straight line.

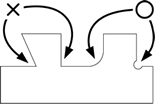

- 3. Set the perforation blades up as follows.

| |

Uncut |

cut |

| Along the grain of YUPO |

0.8 to 1.0mm |

2 to 3mm |

| Across the grain |

0.5mm or less |

2 to 3mm |

- 4. If the perforations touch the edge, the paper will be prone to tearing.

- 5. Make the tension for roll products as low as possible.

(20 kg/m width or less)