- Product Information

Recommended for "Water-based Flexo printing"

- Environmentally Friendly "Synthetic Paper YUPO" x "Water-based Flexo printing" to Develop New Markets

October 15, 2020

Yupo Corporation (Kanda Surugadai, Chiyoda, Tokyo; Masashi Watanabe, President, "Yupo") has verified the suitability of Water-based Flexo printing with some of its synthetic paper YUPO ("YUPO") lineup. This printing method had not been recommended until now due to the lack of any track record, but testing conducted by printing companies and ink manufacturers have verified its excellent printability.

Unticipated applications of YUPO for Water-based Flexo printing. (images are for illustrative purposes).

With technical advances being made with Water-based Flexo printing and a growing market size, Yupo worked with printing companies and ink manufacturers to conduct tests of printing quality, verifying that Water-based Flexo pringing has excellent suitability for printing on certain YUPO products. Testing revealed that Yupo's surface treatment technology gives YUPO a high level of ink adhesion during Water-based Flexo printing, and no longer required "corona discharge process" before printing on general plastic film.

Water-based Flexo printing is an environmentally friendly printing method, as dense sections can be printed using low volumes of ink to limit the amount of volatile organic compound (VOC) and CO2 emissions. This printing method is being used more frequently in Japan for in the beverage label and packing material field, and has also become mainstream in the flexible material (package) printing industry in North America and Europe. The market for WBFP is forecast to growth considerably in the future as made environmentally friendly initiatives are implemented, such as ESG investments and SDGs.

1. Compatible products

- General YUPO (Grade: FPG 60, 80, 95, 110, 130, 150, 200, 250, 300)

Available in rolls with a wide variety of thicknesses. Matte finish for both sides.

- YUPO In-mold Label (Use) (Grade: ISF 105)

In-mold labels can be labeled at the same time as producing the bottle. ISF105 is good for hight-speend forming, and having wide window-molding and anti-static properties.

- *Please contact us for suitable products and grades.

2. Anticipated applications

- Beverage labels (soft drinks, alcohol drinks), food packaging (candy, frozen food bags), etc.

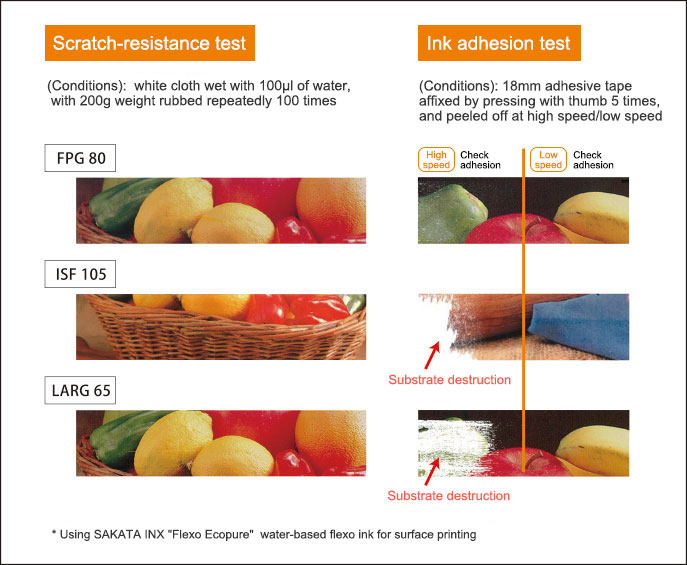

The test results of FPG and ISF with WBFP

YUPO has been verified to provide a high level of ink adhesion and transfer with WBFP.

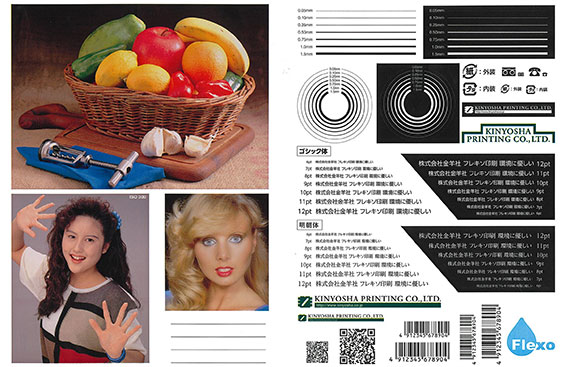

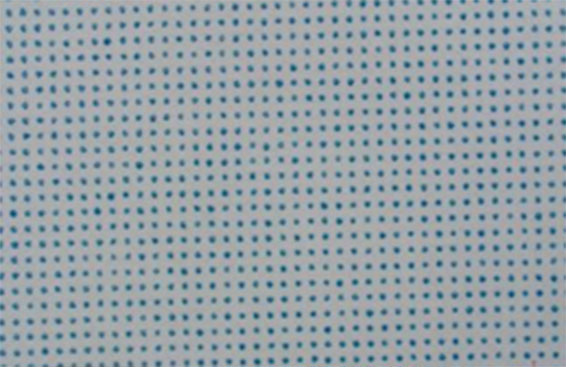

WBFP test samples

- 1.Outstanding ink transfer

- Using SAKATA INX "Flexo Ecopure" water-based flexo ink for surface printing

- Includes printed photo and 5% halftone dot reproduced photo (enlarged 50x)

- 2.Ink adhesion and scratch-resistance performance

- *Substrate destruction: excellent adhesion between YUPO and ink, which the substrate material ended up being destroyed.

Anticipated application (1): Soft drink beverage bottle/can body label

General films are transparent, and to prevent the color of the drink inside affecting the design of the label, a white base needs to be printed with ink when creating labels. YUPO provides better concealment that white ink, which means labels with great designs can be created without being affected by the color of the drink. White ink is no longer needed, which cuts down printing costs and reduces VOC emissions. "Insulated labels" can also be created, which make use of the micro-voids of YUPO to help keep drinks cool, particularly those in plastic PET bottles.

- *1The photograph is for illustrative purposes only.

(Reference) YUPO track record in the package industry

In addition to the water resistance, durability, suitability for printing, and whiteness/opaque appearance base characteristics of YUPO, its broad range of functions like insulating properties, suitability for glue labels, and moisture permeability are utilized for use as In Mold labels, packaging material for cold or frozen foods, and beverage bottle body labels (wrap around labels). Click here for information on examples of applications in the package industry.

Overview of (aqueous flexographic printing) WBFP-compatible products

| Product name | General YUPO (Regular) | YUPO In-mold Label (Use) |

|---|---|---|

| Grade | FPG 60~300 | ISF 105 |

| Thickness | 60µm~300µm | 107µm |

| Features | Standard grade available in rolls, same finish front-rear, with a wide variety of thicknesses. Matte for a more luxurious finish. |

Product with heat seal function on the rear surface. Used for creating In Mold labels by simply printing, with matte finish. Also available with high-strength adhesive for use in the bag-making industry. |

| Applications | Packaging such as wrapping paper and hanging paper | Ideal for food container lid labels, various blow-molded bottle labels, food bags |

| Test sample | Products are available in A4 size. Please inquire for "Roll samples" for test printing. |

|

Inquiries about this product

International Sales and Marketing Department

Sales and Marketing Division

- TEL03-5281-6612

- FAX03-5281-0819

- *"YUPO," are registered trademarks of YUPO CORPORATION.