Dream Paper—YUPO.

Here, we introduce the development history of YUPO CORPORATION.

YUPO CORPORATION began its journey in May 1969 as a creative synthetic paper manufacturer. Since then, we have continued to grow as a leading manufacturer together with the development of the synthetic paper industry, and have developed our business globally based on the unique technological capabilities that we have cultivated. Here, we introduce the development history of the dream paper—synthetic paper YUPO created by endless dreams and taking on the challenge of possibilities.

Background of the birth of synthetic paper—From the demands of the times to a huge boom

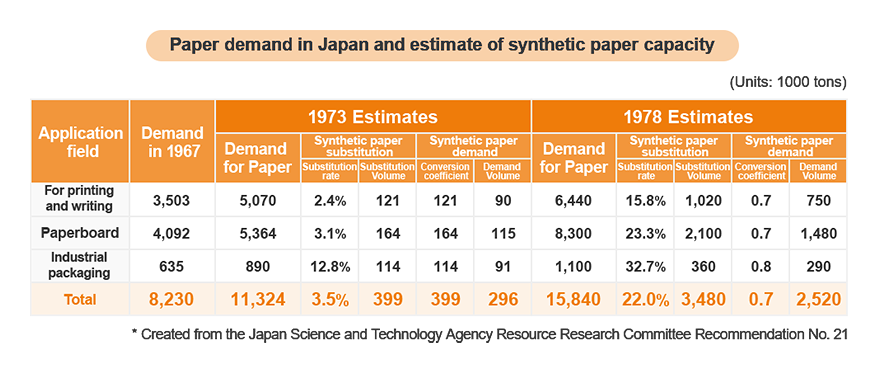

In response to the depletion of forest resources due to the increase in consumption of wood resources and the rise of petrochemicals, in May 1968, the Japan Science and Technology Agency's Resource Research Committee issued a "Recommendation for the Development of the Synthetic Paper Industry". It suggested that synthetic paper, made from inexpensive petroleum resources, would replace natural paper. It made a bold prediction that in ten years, in 1978, out of an estimated 16 million tonnes of paper demand, synthetic paper would account for about 3.5 million tons.

Prior to this announcement, in 1967 Mitsubishi Petrochemical Co., Ltd. (currently Mitsubishi Chemical Corporation) established a materials laboratory and synthetic paper group. It developed synthetic paper based on polypropylene, for which it had already introduced the technology.

Meanwhile, Oji Paper Company (currently Oji Holdings Corporation), which had been conducting research on styrene paper among other areas, was stimulated by the government's recommendation and organized the first meeting of the Synthetic Paper Project Team in September 1968. In the fall of 1970, an estimated 20 companies were planning to commercialize synthetic paper, and a major boom had arrived involving related industries such as petrochemicals, paper pulp, and textiles.

Synthetic paper innovation—The great discovery of microvoids

Initially, the Mitsubishi Petrochemical Synthetic Paper Group used a white pigment and an inorganic filler in polypropylene as a means to obtain a paper-like polypropylene film. The idea was to obtain white color from the white pigment, and writability and printability by forming irregularities on the film surface with the inorganic filler.

However, when prototypes were made with the white pigment, the specific gravity of the film was too high at about 1.2, and the writability was poor; the researchers couldn't achieve the performance they were seeking in synthetic paper.

Then, in 1968. A researcher was making a film without adding white pigment to polypropylene, and by chance created a "white film without white pigment". Inspection revealed that numerous holes, microvoids, and cracks were formed on the surface of the film, and that the microvoids diffused light to provide whiteness. The fine cracks on the surface also improved the writing and printability, and the microvoids reduced the specific gravity of the paper (from 1.2 to 0.77).

Thus, synthetic paper with microvoids and a structure completely different from other synthetic papers was born. The first basic patent for our synthetic paper was filed on March 26, 1968, approximately two months before the recommendations of the Japan Science and Technology Agency's Resource Research Committee were issued.

Fukuro (owl) Unit—A young group passionate about development of synthetic paper

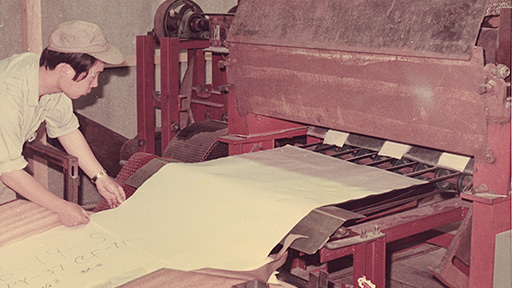

At that time, the Synthetic Paper Group did not have its own development equipment, so it rented equipment from the film lab to conduct experiments. The group could carry out experiments from around 4:00 in the afternoon when the other laboratories had finished their work. They had to clean the equipment thoroughly after their experiments. Any residual synthetic paper material would hinder research on transparent films. The machines had to be taken apart and wiped out carefully, and the piles of prototypes had to be transported to a warehouse more than 1 km away in a cart. At midnight almost every day, a cart passed in front of the guard room... One day the group came to be called the "Fukuro Unit." "We should develop our own synthetic paper with its own structure."——The "Fukuro Unit", with an average age of 21 and about 10 people, worked tirelessly for four years in research toward the birth of synthetic paper before moving to the Kashima Unit 1 Plant.

Tie ups with leading paper and petrochemical manufacturers

Start of synthetic paper business

"We will develop synthetic paper with economics and quality equal to or better than current natural paper, and develop petrochemical synthetic paper with growth potential that can be mass-produced."——On February 12, 1969, Oji Paper Company and Mitsubishi Petrochemical Co., Ltd., who had been conducting synthetic paper research, concluded a joint research agreement to unite the two companies. On May 10, 1969, Oji-Yuka Synthetic Paper Research Institute Co., Ltd. (currently YUPO CORPORATION) was established. The company had a total of four development teams, including a team in charge of the synthetic paper "FP paper" using the microvoids described above, aiming to expand into a wide range of paper fields.

From 1968 to 1969, the company applied for basic patents on the manufacturing technology of the synthetic paper "FP paper" in Japan, Europe and the United States. The media reported that "Oji Yuka have developed a 'dream paper'", and the company received inquiries from about 150 European and American companies. In 1970, the year after the establishment of the company, Oji-Yuka Synthetic Paper Co., Ltd. was established to conduct industrial production. At the end of June 1971, the first synthetic paper plant with a production capacity of 6,000 tons/year was completed in the Kashima Coastal Industrial Zone, Ibaraki Prefecture. The stretching process at the plant was designed based on a biaxially oriented polypropylene film. At that time, the thickness of the polypropylene film was 20 to 30 microns, while that of synthetic paper was 100 microns or more. Despite struggling to improve the equipment to stretch this thick material stably, through tireless efforts, the company successfully started up the plant, now capable of manufacturing products.

Naming and launching the brand "YUPO"

On October 20, 1971, "YUPO" was announced as the product name for FP paper. Out of the 3,000 ideas from employees and their families, including the parent companies, "YUPO", later to also become the company name, was selected based on a review by the selection committee members Sakyo Komatsu, Shinichi Hoshi and others (Click here for the origin). It was temporarily launched in December, and the first real demand was for shopping bags and stickers. After its launch in January 1972, adoption began for maps and binding tapes for vegetables. With the spread of YUPO, we launched translucent YUPO and other products in order to further develop applications, expanded our lineup, and focused on joint development of secondary processing technology for synthetic paper.

Due to the oil shock, from quantity to quality—180-degree turnaround

In the midst of starting to export to the United States in partnership with an overseas paper manufacturer, a bolt from the blue occurred. The first oil shock was triggered by the outbreak of the fourth Middle East war in October 1973. As a result, prices of main raw materials soared in December. The premise of "creating an alternative to natural paper from cheap petroleum" collapsed, and many synthetic paper manufacturers were forced to withdraw due to poor profitability. In the face of this challenging environment, we decided to continue our business, finding the potential for superior features unique to YUPO, although the scale was slimmed down. The sales policy was changed from replacing natural paper to providing high-performance applications that natural paper could not achieve. Assuming a large price difference with natural paper, we restarted as a supplier of an "excellent new material that combines the characteristics of synthetic resin film and paper."

Quality improvements for total improvement of YUPO

As a result of conducting market development utilizing functions unique to YUPO under the new policy, we cultivated new applications in the fields of commercial printing, adhesive paper, specialty paper, bags/envelopes, packaging, and building materials. By around 1978, unique demand for YUPO was taking hold. Here, we undertook a total improvement of YUPO with the aim of further establishment and breakthrough. The aim was to drastically solve the problem of "aging" of YUPO, which had been occurring for a long time, and it required major changes in raw materials and manufacturing processes to achieve. Although there was a risk that we would not be able to return once we made the change, the results provided significant improvements in weather resistance and punching. Pre-sales began for some grades, and in 1981 we switched over completely. The product was launched as "YUPO FPG", and forms the basis of the current YUPO.

With the strong boost from the quality improvement, the company achieved profitability for the first time in 1981. It had already been more than ten years since the foundation.

Winner of Mainichi Industrial Technology Award

In 1979, Koji Onishi, a Part-time Director at YUPO (Oji Paper Vice President) Naoichi Takashima (Mitsubishi Petrochemical Managing Director)* received the 30th Mainichi Industrial Technology Award in recognition of their great contribution to the success of the development and industrialization of synthetic paper manufacturing technology. This was an exciting event for YUPO, which had developed YUPO and pioneered a new market for synthetic paper, and it became a driving force for the further development of our business.

- * Naoichi Takashima received the Blue Ribbon Medal in 1991 for "Development of Synthetic Paper Manufacturing Technology".

YUPO's development

YUPO, born from the needs of the times, has been developing various products and applications in response to changes in the times and society, and has been providing unique value globally from its birth to the present. At YUPO CORPORATION, we will continue to work on product and application development in anticipation of the needs of the times in order to enrich society through materials using the technology we have cultivated up to now and the spirit of challenge we have cherished since our founding.

A stone monument at the KASHIMA FACTORY contains the message of former Chairman Shigeru Tanba,

the father of YUPO, who contributed for about 40 years from the birth of YUPO

to its commercialization and subsequent development.